REFurBISHMENT AND RETROFITtING

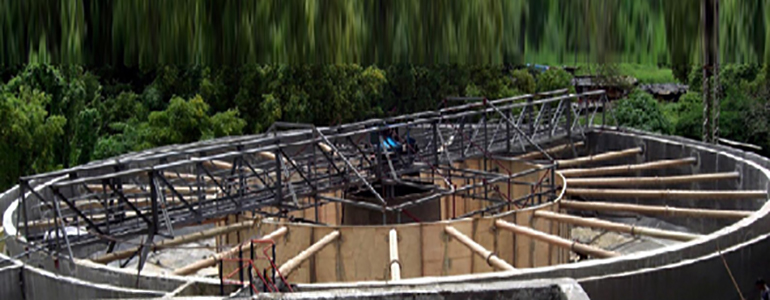

Retrofit Existing Wastewater Treatment Plant - Aeration System

Upgrading your treatment plants aeration system can provide significant energy savings. Examples of energy saving opportunities include:

- Replacing aging membrane disc diffusers with advanced performance Aquarius EPDM membranes.

- Replacing ceramic diffusers with new sub-plates and membrane disc diffusers.

- Adding additional air distributors and diffusers to systems that are dealing with increased load to improve system performance.

- Updating mechanical or coarse bubble aeration systems to fine bubble.

- Replacing leaking or failed piping systems.

- Rapid response and shipment available.

Waste water treatment companies like Achme Water brings over 10 years of biological treatment and aeration design and manufacturing expertise to the industry.

Let Achme be your one stop shop for waste water treatment plant design, aeration products, and maintenance.

Some of the assets that Achme brings to your project include:

- Diffused aeration performance data base developed using the latest version of the ASCE protocol for the Measurement of Oxygen Transfer in Clean Water. This allows us to develop designs with a high degree of accuracy.

- Project management and design experience based on hundreds of successful projects worldwide.

- The ability to respond quickly to design requests and contractor needs.

- The expertise that has developed the most energy efficient membrane disc diffuser, independently verified.

- High volume production capacity.

Retrofitting or upgrading mechanical or coarse bubble aeration systems can yield significant energy savings. Let Achme be your one stop shop for wastewater treatment package plant design, aeration products, and plant maintenance.

Candidates include:

- Wide band coarse bubble systems.

- Diaphragm style, duckbill type, single drop diffusers plants.

- Mechanical low and high speed aerators.

- Sparged Turbine aerators.

- Jet aeration systems.

- Oxidation ditch rotors and disc aerators.

It is not uncommon to realize 40 – 60% energy savings retrofitting these types of systems to fine bubble aeration.